Products

Plywood is one of the most useful and common materials used in building houses and other structures. Its flexible and lightweight characteristics make it very much popular in all architectural masterpieces. Aside from that, it is also structurally stronger than the natural wood, which makes it also very much ideal for making furniture. Whether you are looking for high quality birch or maple plywood for making your bedroom furniture or for your living room furniture, one of the best domestic maple plywood or Baltic birch plywood materials that you can find in the industry is from International Plywood. Our products make stable and strong furniture, which are really very much advantageous because they are inexpensive and can be built and modified easily. We carry Cabinet grade Birch Plywood, Maple Domestic Plywood Pre-finished and natural, Cdx Plywood for flooring underlayment, 5/8 cdx for roof sheathing and 1/2 cdx for sheathing walls.

DUNNAGE

Covering manhole and protecting lawn before the backhoes rives or even temporarily, sheeting up the broken windows do not always needs for a very expensive plywood. This is mainly the reason why we offer economical options that are classified under Dunnage grade. The sheet are very rough around its edges and slightly utilized by mill that we mainly obtain from. In addition, because of the utility grade’s nature, you should not anticipate utilizing it for other purposes beyond a simple cover of the ground.

PARTICLE BOARD

One of our major products that primarily falls under this type is the fiberboard. This is a very common product, while K3 and Melamine are two of the many products that are widely used. Melamine is considered as very cost effective essential for the cabinetry applications. In addition to that, this is also available in variety of patterns and colors. K3 on the other hand could be incorporated into a cabinetry and is commonly used in some unseen areas like floors’ underlayment or support.

MAHOGANY/SPRUCE/SANDED FIR

There are instances wherein your own project may call for something, which is primarily set up from the regular sheathing. Domestic sanded could be very good option. If you are looking for any type of products, the quality would be similar, yet the name that is given to the grade might be different. It is very common in the US to use combination of letter grade to refer to sanded plywood grade including ACX or BCX. Most of the grades that are available today are in Fir, but not that always available in spruce and mahogany.

EXOTICS

These are typically utilized in the interior application. Some of the mills produced exterior marine grade of plywood faced with Okoume, Meranti, or Keuring. Generally, because of the expense and nature of the wood, they are mostly used for indoor purposes.

CONSTRUCTION GRADE

Spruce or fir sheathing in standard o degrade and the most common types of grade that are used in building project construction phase. O.S.B is another common type of item, in which its uses are not that versatile. This is mainly because of limitations to the strength of the product and most of all the longevity in the environments that are exposed to different elements and moisture.

H.D.O- CONCRETE FORMING PLYWOOD

High density overlay or HDO is used for the concrete forming. On the other hand, the highway grade is also among the best options for the paint ready panel that is highly water resistant. This is the reason why there is a need to ask for the advice of someone who is expert when it comes to this kind of product before you engage in the construction. Because even if they look the same, bear in mind that one is made in order to resist while the other one is made to accept the product.

M.D.O- EXTERIOR SIGN BOARD

Medium density overlay or MDO is used in order to create an exterior signage both finished with the decals and painted. While the panel creation was primarily inspired by the need of creating reliable and superior signboard, the practical and actual use of this type of material could substitute other options.

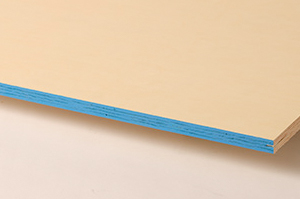

PRE-FINISHED HARDWOOD

All of the pre-finished panels that we offer are mainly finished with the use of the UV baked process. Ultra Violet paint is primarily applied in almost five layers to panels and along with the three-epoxy sealer in order to complete the panel itself.